What are the disassembly and assembly requirements for centrifugal fan cleaning?

After the centrifugal fan has been used for a long time […]

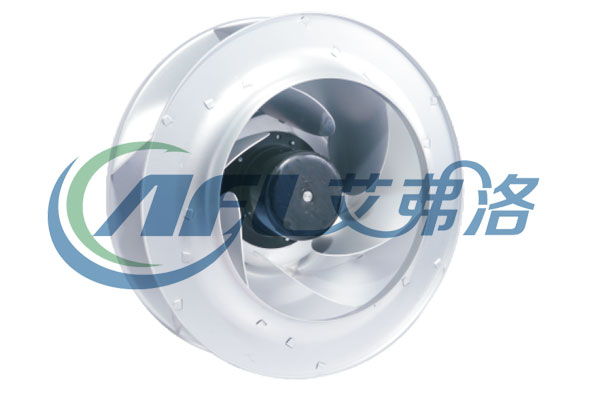

After the centrifugal fan has been used for a long time, it needs to be cleaned. In the process of cleaning, it is necessary to encounter some places that are difficult to clean. In order to clean the entire centrifugal fan thoroughly, the centrifugal fan needs to be disassembled. Because the internal structure of the centrifugal fan is relatively fine, the process of disassembling the fan is also more complicated, so there is no error in the disassembly process. At the same time, the process of disassembling the fan is completed. After the parts of the centrifugal fan have been cleaned, they must be reassembled. What are the main points worthy of our attention when reassembling?

If the two parts of the centrifugal fan are not disassembled first, the overall cleaning of the entire fan cannot be completed; the second thing we need to pay special attention to during the cleaning process is that the part of the motor directly connected to the fan cannot be disassembled Clean to prevent mechanical failure caused by motor burning.

Disassembling the fan: First, disassemble the processing casing and the bearing box. If these two parts are not disassembled first, the entire fan cannot be cleaned as a whole. The second thing we need to pay special attention to during the cleaning process is that it is not possible to disassemble and clean the part of the motor directly connected to the fan to prevent mechanical failure of the motor from burning.

After the complete cleaning of the centrifugal fan is completed, the parts must be assembled. First, use the pair of inclined shims to level it and place it on the foundation. Secondly, whether it is cleaning or assembling the centrifugal fan, the adjustment mechanism is first tested. , Check the flexibility of its rotation.

Assemble the fan: first use a pair of inclined shim irons to level it and place it on the foundation. Secondly, whether it is cleaning or assembling the centrifugal fan, the adjustment mechanism is first tested to check the flexibility of its rotation.

In addition, everyone cannot ignore the selection of centrifugal fans. For ventilation systems with noise requirements, you should first choose a centrifugal fan with high efficiency and low impeller circumferential speed, and make it work at the highest efficiency point; it should also be based on the ventilation system. For the propagation mode of the generated noise and vibration, take corresponding measures for noise reduction and vibration reduction.

It can be seen that when disassembling and assembling the centrifugal fan, we should start with those points. We pay attention to these points to ensure the accuracy of the actual disassembly work and reduce the possibility of problems during assembly after the cleaning work is completed. , To ensure that users can finally use the fan normally and ensure that the production work is not affected.